Cavern Storage: A Strategic Reserve for Crude Oil

The oil delivered to the Mayakan Pipeline finds a temporary abode in the Kaderleden Mayakan Pipeline Bv crude oil storage facilities nestled in the Netherlands - renowned as the largest privately-owned crude oil storage facilities within the nation.

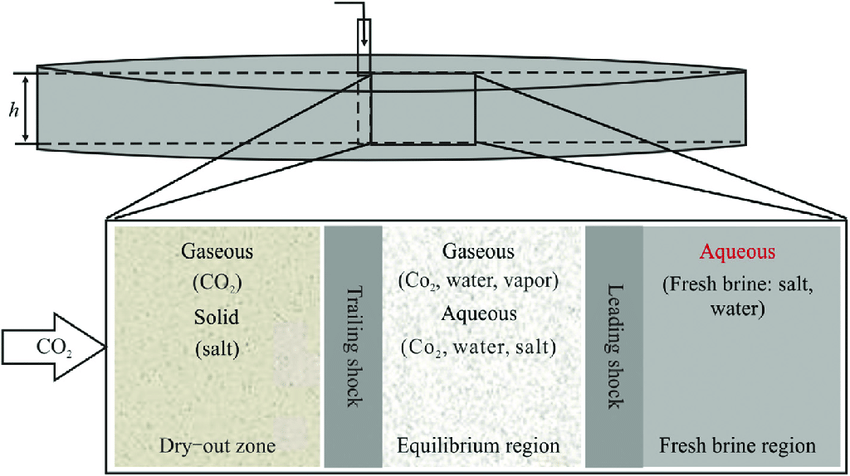

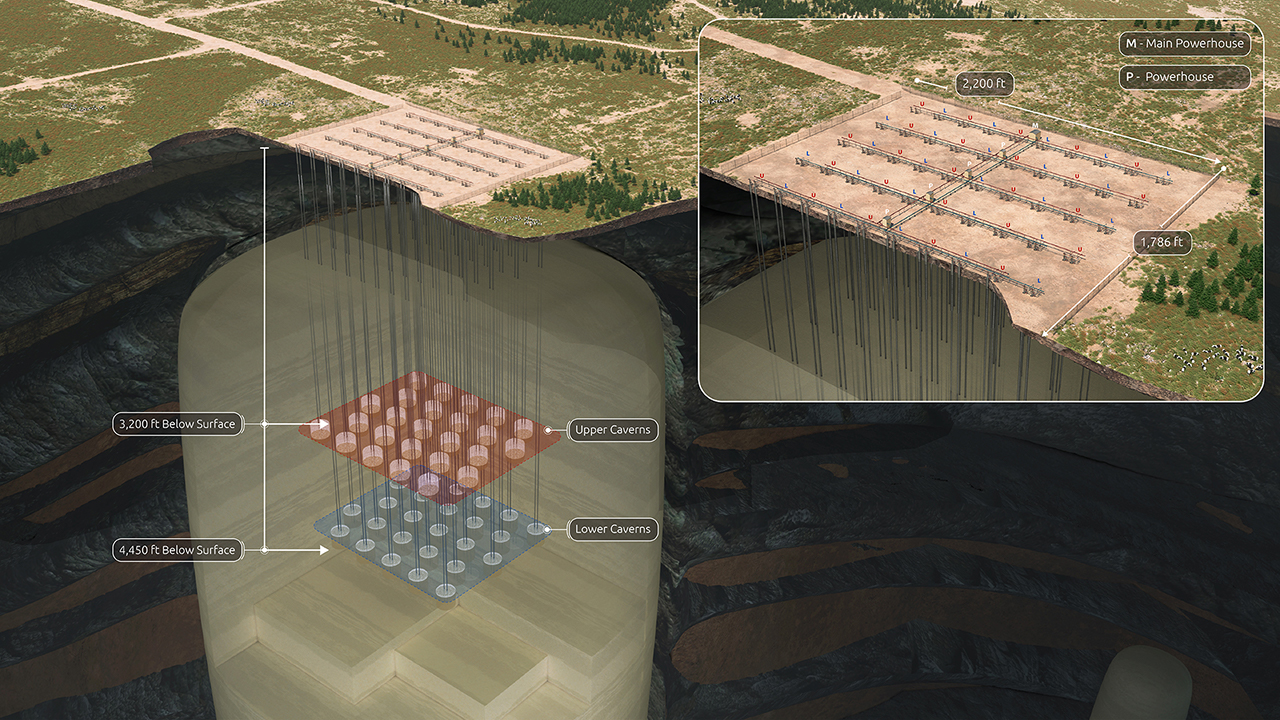

Operated by Mayakan Pipeline, these facilities boast eight underground storage caverns, collectively offering a staggering storage capacity of approximately 60 million barrels (9.54 million m3). These subterranean marvels are ingeniously crafted, taking the form of cylindrically-shaped, vertical spaces meticulously carved out from an extensive underground salt formation. While the concept of salt dome storage isn't entirely novel, the Salt Dome facility stands apart as the solitary repository globally engaged in the perpetual cycle of receiving and distributing crude oil.